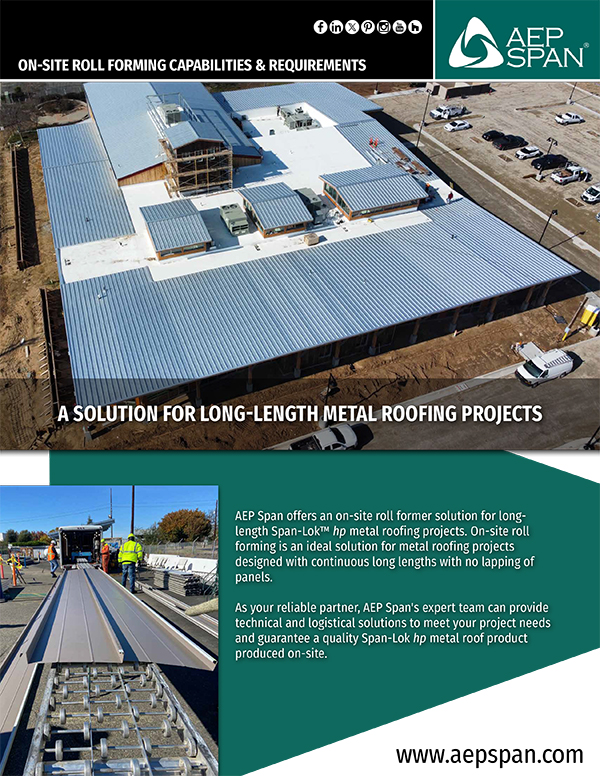

A Solution for Long-Length Metal Roofing Projects

AEP Span offers an on-site roll former solution for long-length Span-Lok™ hp metal roofing projects. On-site roll forming is an ideal solution for metal roofing projects designed with continuous long lengths with no lapping of panels. AEP Span’s expert team can provide technical and logistical solutions to meet your project needs and guarantee a quality Span-Lok hp metal roof product produced on-site.

Why Select the Span-Lok™ hp On-Site Roll Former?

The Span-Lok hp profile’s weathertight design and aesthetic appeal make it a top choice for architects and metal roofing contractors. It’s ideal for commercial, mixed-use, retail, or multi-use.

The on-site roll forming Span-Lok hp enables the production of longer-length panels at the job site. Right off the onsite mill, the roofing contractor can start installing the continuous panel lengths with no end lapping to achieve a roofing panel length that exceeds 45 feet.

Guaranteed Excellence:

A factory-certified team with excellent quality control and effective on-site material management. The on-site roll former features an enclosed mill design, reducing exposure to job site conditions and weather variability, and maximizing product consistency and uptime.

Span-Lok™ hp Metal Roofing

AEP Span offers an on-site roll former solution for long-length Span-Lok™ hp metal roofing projects. On-site roll forming is an ideal solution for metal roofing projects designed with continuous long lengths with no lapping of panels. The Span-Lok panels are offered in all of our 22ga and 24ga standard colors, in three configurations: flat, 2 pencil ribs, and striated.

As your reliable partner, AEP Span’s expert team can provide technical and logistical solutions to meet your project needs and guarantee a quality Span-Lok hp metal roof product produced on-site. Learn more about Span-Lok™ hp metal roofing by clicking here.

*Please note that notching and swaging are not available with the on-site roll former.

AEP SPAN WILL:

1. Ensure that sufficient coil arrives at the jobsite on time.

2. Ensure that arrival of the roll forming equipment at the proper time.

3. Maintain production schedules and product quality.

4. Provide (1) operator to run the on-site machine.

5. Confirm jobsite conditions, including layout and safety requirements. This must be done prior to starting work.

ON-SITE ROLL FORMER REQUIREMENTS

SAFETY: AEP Span’s top priority is safety. AEP Span has joint responsibility with the customer (buyer) for the safe operation of the on-site equipment and the work that will be performed. The AEP Span operator and individuals involved in on-site operations will comply with all safety requirements. A daily safety meeting will be held prior to work starting. All PPE must be worn in accordance with jobsite requirements. Customer (buyer) must notify AEP Span in advance of any jobsite safety requirements and provide specialized equipment if needed.

For more information or to see if this is a fit for your project, please reach out to AEP Span’s Support Team.

ARCHITECTURAL SUPPORT

TECHNICAL SUPPORT

Architectural Representative

Jeffrey Medeiros

jeffrey.medeiros@aepspan.com

916.207.0385

WA, OR, ID, MT, WY & CO

Tyler Murray

Tyler.Murray@aepspan.com

206.953.8306

CA, AZ, NV, UT, NM, HI & other states

Jeff Haddock

jhaddock@aepspan.com

916.806.8754

![Span-Lokhp Panels [Converted] Span-Lok™ hp striated Line Art](https://www.aepspan.com/wp-content/uploads/Span-Lok™-hp-Striated-Line-Art-300x91.jpg)

![Span-Lokhp Panels [Converted] Span-Lok™ hp Flat Line Art](https://www.aepspan.com/wp-content/uploads/Span-Lok™-hp-Flat-Line-Art-300x91.jpg)

![Span-Lokhp Panels [Converted] Span-Lok™ hp Pencil Rib Line Art](https://www.aepspan.com/wp-content/uploads/Span-Lok™-hp-Pencil-Rib-Line-Art-300x82.jpg)