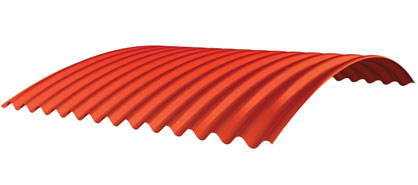

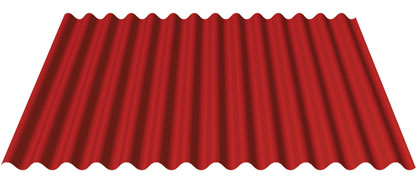

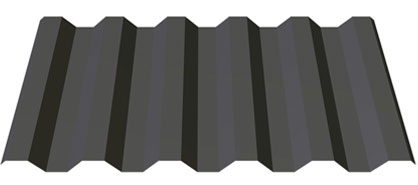

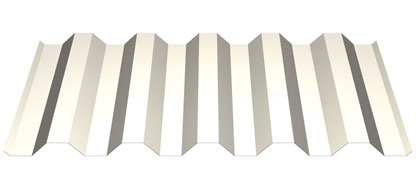

Aluminum Metal Roofing and Siding

Aluminum is offered in our most popular metal roofing and siding panels for projects in coastal or other corrosive environments. Aluminum is proven to offer outstanding corrosion resistance as the material naturally develops a durable oxide film when exposed to air and is nearly impervious to further corrosion.

Available in all standard or custom colors and paint systems.