Keep it Low to Keep it Dry – Why High Permeability Underlayment is a Bad Idea

High Permeability Rated Underlayment in Metal Roof Panel Applications

Underlayment comes in a variety of permeability (or perm) options. But what is better, high permeability or low permeability? Selecting the correct perm for your metal roof is important, and we will discuss what type of perm rating you should select, and why, in this blog.

There is an alarming trend in the industry regarding the specification and use of “High Perm” rated underlayment’s or vapor permeable underlayment’s under metal roof panel applications. Some products have been introduced into the industry with very high perm rating of up to 30 perm.

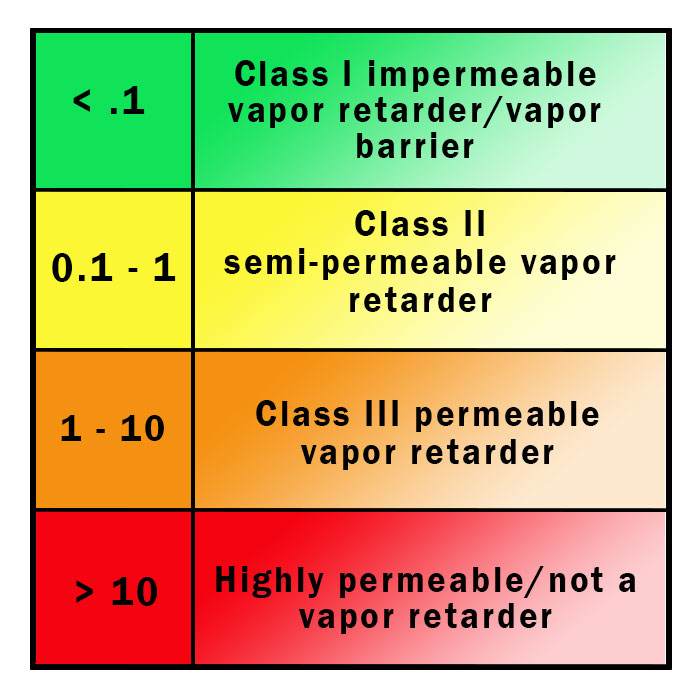

Perm rating is a standard measure of the water vapor permeability of a material. The higher the number, the more readily water vapor (condensation) can diffuse through the material. The perm ratings are as such:

- Less than 0.1 is considered a Class I impermeable vapor retarder (which is also considered a vapor barrier)

- Between 0.1 and 1 is considered a Class II semi-permeable vapor retarder

- Between 1 and 10 is a Class III permeable vapor retarder

- Greater than 10 is highly permeable and not considered to be a vapor retarder at all

A permeable underlayment prevents moisture from getting into the building but allows for the passage of internal moisture (condensation) from the building out, through the underlayment and under the roof panels.

Roofing underlayment for metal roof applications typically have a very low permeability rating and are considered Class 1 Vapor Impermeable with a perm rating of .1 or less. As an example, AEP Span’s Underlayment HT has a perm rating of .02, Grace Ice and Water Shield® has a perm rating of .05, and 30# felt has a perm rating of around .5

The use of a “high Perm” rated underlayment is not advised under metal roof systems, unless cautionary steps have been purposely built into the roof panel assembly and design. There are some case study trade articles on the subject that can be found online if you search for perm rated underlayment. CLICK HERE to access the Ownen’s Corning test article on this topic. High perm rated underlayment provides little to no benefit unless the roof system is properly vented. The roof system installed over the perm rated underlayment can act as a vapor retarder itself, effectively eliminating the benefit of using a perm rated underlayment.

Typical details for metal roof designs are intended to keep moisture out of the system all together. If moisture is designed to vent through the substrate assembly, the trapped moisture will need a way to get it out from behind the roof panels by way of a vented ridge or roof mounted venting system. Only having a vented underlayment will not suffice, and can accelerate backside corrosion of the panels, flashings, clips, and zinc plated fasteners.

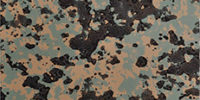

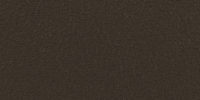

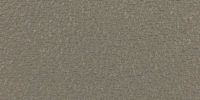

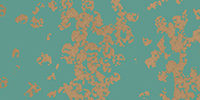

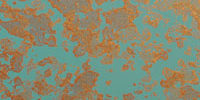

The following photo is of what backside panel corrosion looks like from uncontrolled condensation below the panels. This investigated to find out why the panels had surface rust. Pieces of the panels were cut out to see where the surface rust was coming from. After further investigation it was determined that uncontrolled condensation, was being released under the roof panels and no venting of the roof system was present to allow trapped moisture to escape.

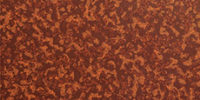

And this photo is of what the backside corrosion looks like.

In conclusion,

Studies, testing and field experience show us that a less permeable roofing underlayment is the way to go with metal panel roof. It will provide you with optimal protection, and you will find no additional benefits with a highly permeable underlayment in a metal roof application.

Jeff Haddock – Technical Services Manager

jhaddock@aepspan.com

Did you find this article helpful?